Powder Coating Equipment Factories are the backbone of the powder coating industry, providing essential tools that turn ordinary metal pieces into works of art. As a satisfied customer from a large manufacturing plant said, "The high-quality powder coating equipment from reliable factories has revolutionized our production process, giving us flawless finishes every time." Another entrepreneur shared, "Investing in equipment from reputable powder coating equipment factories is the smartest decision I've made for my business, boosting both efficiency and product quality."

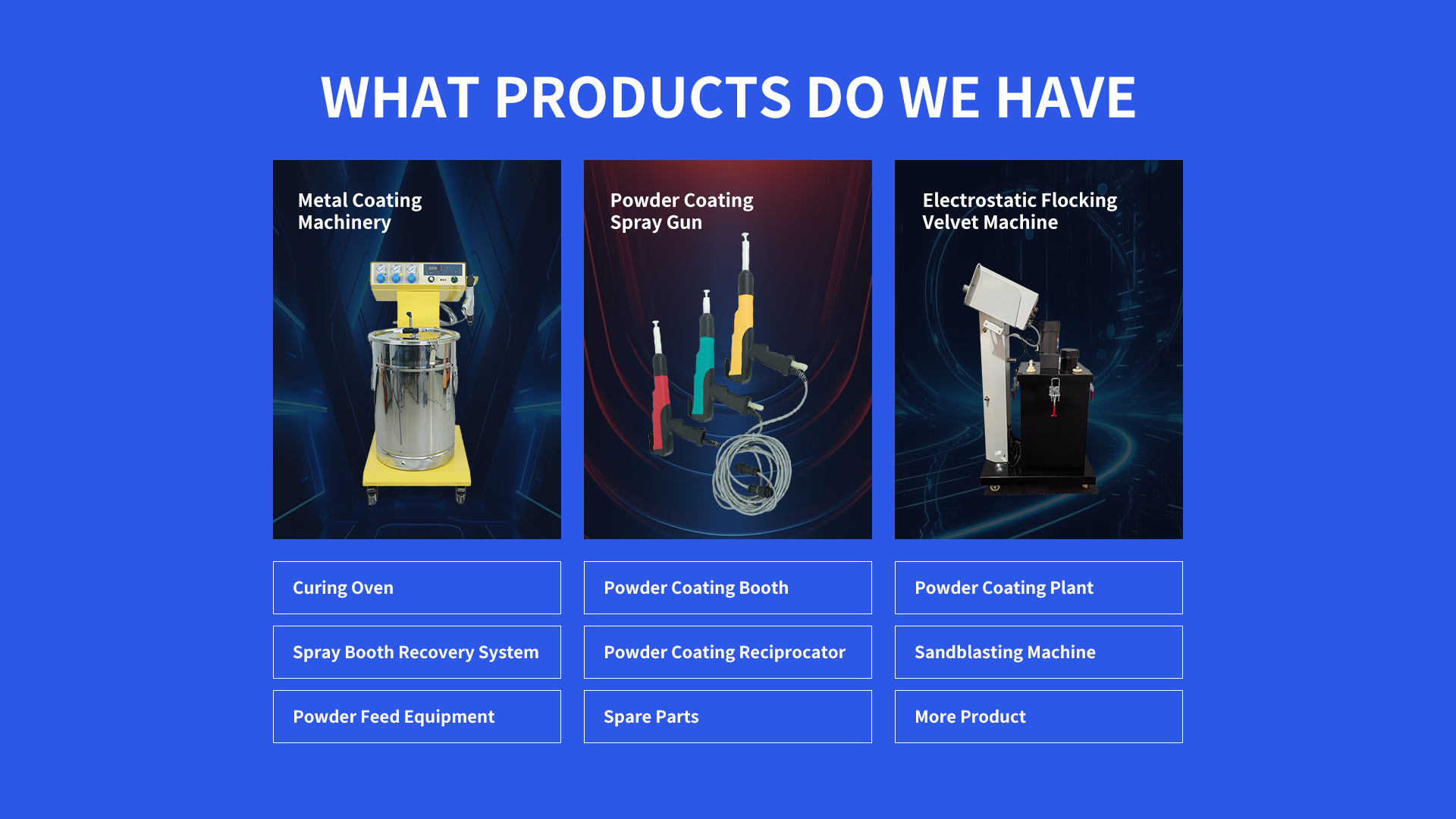

Powder Coating Equipment from factories typically includes powder coating guns, powder feeders, curing ovens, and powder reclaim systems. A powder coating gun has a handle, a powder flow control mechanism, and a nozzle. Electrostatic guns are equipped with an electrostatic charging system to enhance powder adhesion. The powder feeder stores and supplies powder to the gun. Curing ovens are constructed with heat-resistant materials and have heating elements and a circulation system for even heat distribution. Powder reclaim systems use filters or cyclones to recycle oversprayed powder.

These equipments find wide applications in the automotive industry for coating car bodies, parts, and wheels. In the furniture sector, they are used to coat metal frames, improving appearance and durability. Electronics manufacturers rely on them to coat metal enclosures for protection. Additionally, small-scale workshops and DIY enthusiasts use powder coating equipment for customizing metal items like home decorations and tools.

The prices of Powder Coating Equipment from factories vary. Basic sets for small-scale or DIY use, including a simple powder gun and a basic powder feeder, can cost from $500 to $2000. Mid-range equipment with better quality components, such as electrostatic guns and more efficient powder reclaim systems, ranges from $2000 to $8000. High-end industrial-grade equipment, featuring advanced curing ovens and precise control systems, can exceed $8000.

Before use, assemble all components correctly and ensure proper grounding. Fill the powder feeder with the appropriate powder. Adjust the powder flow rate and electrostatic charge (if applicable) according to the workpiece. Hold the gun at a consistent distance (around 15-20 cm) from the workpiece while spraying. After spraying, place the coated item in the curing oven at the recommended temperature and time.

Consider your production volume. For high-volume production, choose high-end equipment from well-established factories. Evaluate the types of workpieces; complex shapes may require equipment with adjustable spray patterns. Set a budget and compare prices, but also focus on the quality and after-sales service provided by the factory.

Wear protective gear like masks, goggles, and gloves to prevent powder inhalation and skin contact. Ensure good ventilation in the work area to avoid powder accumulation. Keep the equipment away from flammable materials, especially the curing oven.

The design of

Powder Coating Equipment from factories is rational. The powder reclaim system reduces material waste, saving costs. Precise control features in the equipment ensure a high-quality finish, reducing rework. The durability and reliability of the equipment justify the investment.

Q: What if the

Powder Coating Equipment from the factory doesn't meet my expectations?

A: Check the user manual and ensure you are using it correctly. If there are still issues, contact the factory's customer service for support. They may offer solutions like repairs, replacements, or additional training.

Q: Can I use different powder types with the equipment from a powder coating equipment factory?

A: Yes, but make sure to clean the equipment thoroughly between powder type changes to avoid contamination. Some powders may require specific adjustments to the equipment settings.

Q: How often should I maintain the

Powder Coating Equipment from the factory?

A: Clean the powder gun, feeder, and reclaim system after each use. Inspect the curing oven and other components monthly for any signs of wear or malfunction. Regular maintenance can extend the lifespan of the equipment.

Q: What if the curing oven from the powder coating equipment factory has temperature fluctuations?

A: Check the temperature control settings and sensors. If the problem persists, contact the factory's technical support. They may need to calibrate or repair the oven.

Q: Can I get spare parts for the powder coating equipment from the factory easily?

A: Reputable factories usually provide spare parts for their equipment. It's advisable to check with the factory about the availability and cost of spare parts before purchasing the equipment. This ensures smooth operation and reduces downtime in case of any component failure.

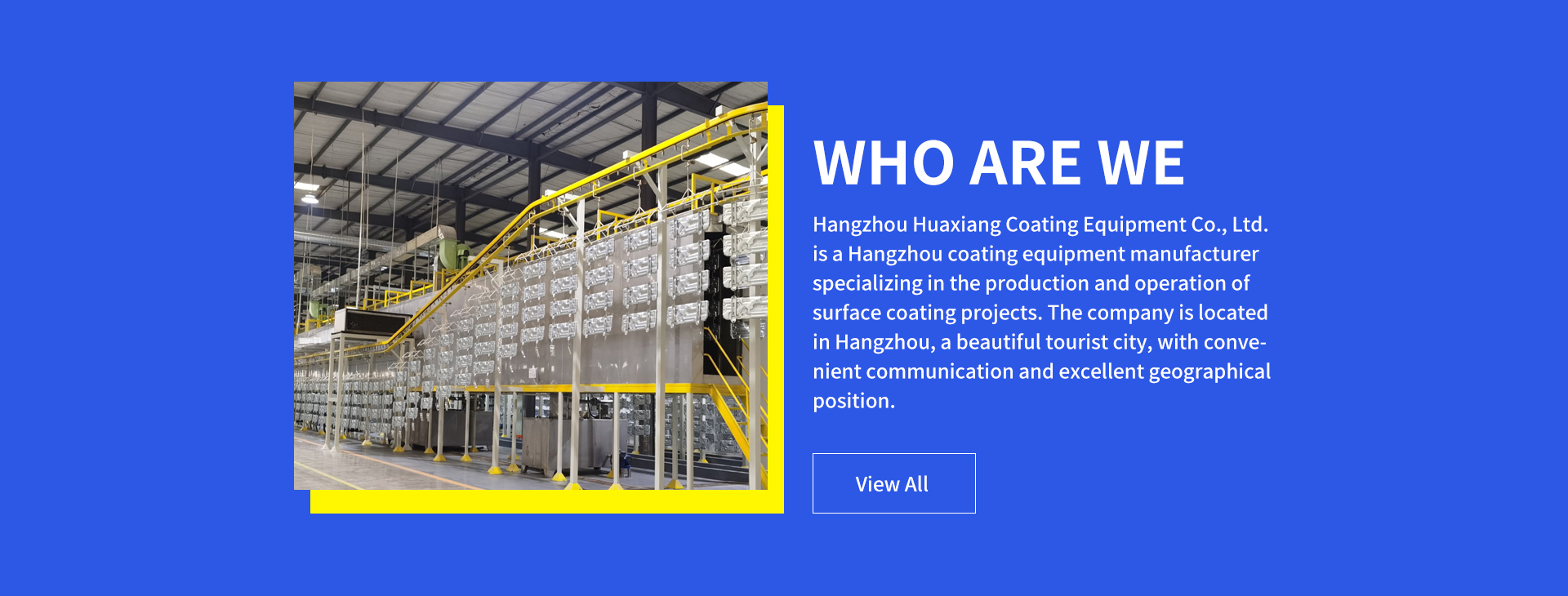

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com